KNOWLEDGE MODEL

Streamline and automate the troubleshooting and fault isolation process.

MAXIMIZE EQUIPMENT UPTIME, MINIMIZE DOWNTIME

Equipment downtime is costly to your mission and your organization’s bottom line. The ONeMIND knowledge model maximizes equipment operability by automating the troubleshooting process for technicians of any experience level.

With intelligence backed by an organized collection of symptoms, tests, and repair procedures for your equipment, the ONeMIND solution dynamically responds to the user with a prioritized list of recommended repair procedures. Rich logging capabilities identify trends in your equipment performance today, keeping your equipment at its best tomorrow.

INTELLIGENT PROBLEM-SOLVING FOR RAPID EQUIPMENT REPAIR

Uses past success and failure rates along with weighted attributes to compile the order and reduce repair time and repair costs.

Captures intellectual capital as experienced field technicians develop those comprehensive lists of symptoms, possible solutions, historical experience, and procedures.

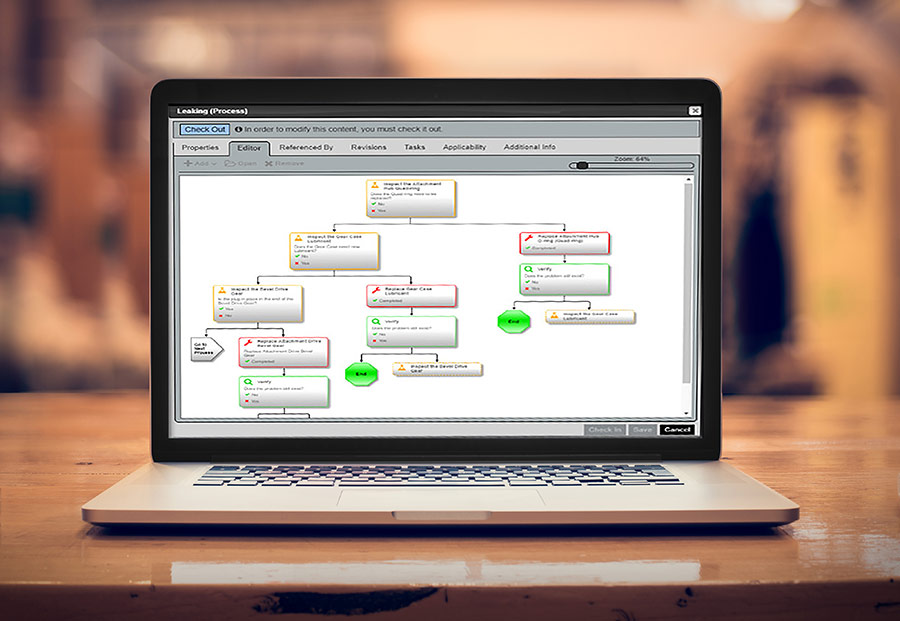

Authors can build a library of symptoms, test procedures, and repair procedures and relate those elements together for use by field service personnel.

Procedures have built-in logic based on weighted attributes such as cost, time, availability of parts, crews, or equipment required.

Learns from each use and adjusts likely scenarios. As time progresses, reliability rate of successful procedures increases.

Interoperability with existing systems and the rest of the ONeSOURCE solutions as needed.